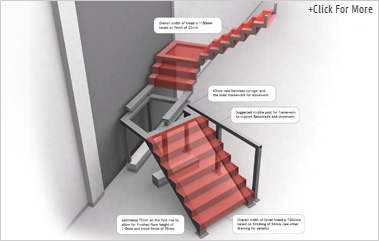

Covent Garden - London

Feature Staircase - Finished in Portland stone & Timber with a heavy internal steel core structure

Design Stage

Working from a number of 2D CAD drawings from the Architect and Engineer we constructed a concept model in 3D in order to highlight some areas that needed further discussion and agreement on. As there were 2 different finishes on the staircase - Portland Stone on the lower section and Timber on he top, it was vital that the core steel structure made allowances for the different depths on finishes to maintain an equal rise throughout the finished staircase.

Once confirmation was received to proceed, a full set of fabrication drawings were created and approved.

The Construction & Installation

In most cases when designing a steel structure for a staircase it is possible to fabricate the item in manageable sections that can be bolted together on-site. However due to the limited available space between the steel framework and the timber finish and the shear weight of the steels, it was necessary to design the stairs with a minimal bolted connections and then to fully weld the structure on-site